Industry News

How do temperature extremes affect the performance of steel fasteners?

Brittle Fracture Risk: At temperatures below the ductile-to-brittle transition temperature (DBTT), steel fasteners become highly susceptible to brittle fracture...

Mild steel is carbon steel with a carbon content o...

Medium carbon steel is carbon steel with a carbon ...

Alloy steel In addition to iron and carbon, other ...

Bearing steel, also known as high carbon chromium ...

Fasteners must be manufactured from raw materials,...

Special-shaped steel refers to steel whose shape i...

Brittle Fracture Risk: At temperatures below the ductile-to-brittle transition temperature (DBTT), steel fasteners become highly susceptible to brittle fracture. This is a catastrophic failure mode characterized by little or no plastic deformation prior to failure. To mitigate this risk, fasteners intended for low-temperature applications should be selected based on their low-temperature toughness properties, such as Charpy impact energy values.

Reduced Ductility: The ductility of steel decreases significantly at low temperatures, making the material less able to absorb energy and deform plastically before failing. This can lead to premature failure under cyclic loading or impact conditions. To address this, fasteners can be designed with increased cross-sectional area or selected from materials with inherently higher low-temperature ductility.

Thermal Stress: Rapid temperature changes can induce thermal stresses within the fastener, which can exacerbate the effects of low temperature on material properties. Proper insulation and temperature control measures should be implemented to minimize thermal gradients and stresses.

Strength Degradation: As temperature increases, the yield strength and ultimate tensile strength of steel fasteners typically decrease. This reduction in strength can compromise the fastener's ability to withstand loads and maintain structural integrity. To compensate, fasteners for high-temperature applications should be selected based on their elevated temperature strength properties.

Creep and Relaxation: At high temperatures, steel fasteners can experience creep and relaxation, leading to gradual deformation and loss of preload. This can significantly reduce the effectiveness of the fastener in maintaining joint integrity. To mitigate creep and relaxation, fasteners can be designed with larger cross-sections or selected from materials with improved creep resistance.

Oxidation and Corrosion: Elevated temperatures accelerate the oxidation and corrosion of steel, leading to material degradation and potential failure. Proper surface treatments, such as galvanizing or applying corrosion-resistant coatings, can help extend the service life of fasteners in high-temperature environments.

Thermal Expansion: High temperatures cause steel to expand, which can lead to dimensional changes and potential issues with fit and function. Designers must account for thermal expansion when selecting fasteners and specifying installation procedures.

Material Selection: Carefully select fasteners based on the specific temperature range and environmental conditions they will encounter. Consider factors such as low-temperature toughness, elevated temperature strength, creep resistance, and corrosion resistance.

Design Considerations: Design fasteners with appropriate cross-sectional areas and geometries to accommodate the effects of temperature extremes. Consider using preload indicators or locking mechanisms to maintain preload in high-temperature applications.

We are a source manufacturer of professional steel wire, we also have our own international trade department, we produce and sell by ourselves.

Ningbo SunRise Refined Metal Wire Material Co., Ltd. is China Custom How do temperature extremes affect the performance of steel fasteners? Suppliers and How do temperature extremes affect the performance of steel fasteners? Factory. We not only brought in 10 sets of spheroidizing annealing furnaces, dozens of metal wiredrawing equipments and twoworld's leading automatic phosphating pickling lines, but also engaged senior engineers as consultants fromTaiwan. The raw material that we use are supplied by the well known suppliers such as Bao Steel Co., Ltd and Xingtai lron & Steel Corp., Ltd. Also, the domestic lron & Steel manufacturers can be nominated by our customers.

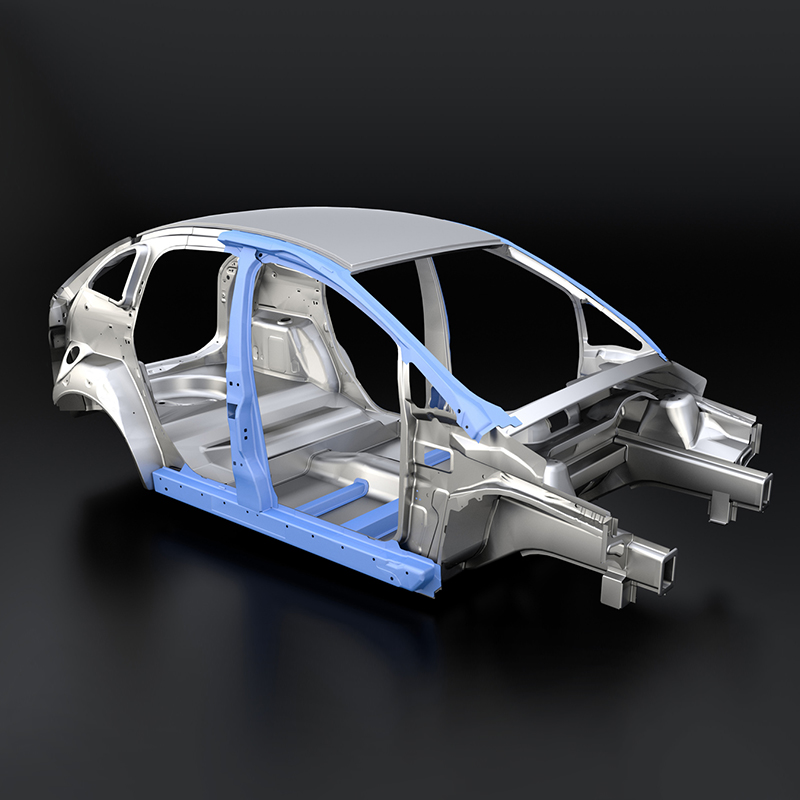

We mainly produce steel wire made of alloy steel, bearing steel, free-cutting steel, high-quality carbon structural steel, low-alloy high-strength structural steel and other materials as raw materials. The annual output is 360,000 tons. It is one of the largest finished wire production bases in Ningbo. We serve all kinds of fasteners, special-shaped parts, automotive fasteners, wind power, petroleum and other fields. Ningbo SunRise is able to meet the high quality requirements of our customers throughout the whole operation process from raw materials to finished products.

Brittle Fracture Risk: At temperatures below the ductile-to-brittle transition temperature (DBTT), steel fasteners become highly susceptible to brittle fracture...

Corrosion Risk: Despite the enhanced corrosion resistance imparted by the phosphate coating, the steel can still be susceptible to corrosion under certain condi...

Directionality of Brushed Lines: Brushed process steel is characterized by fine, linear abrasions that create a distinctive surface texture. Under directional l...

High Hardness: Bearing steels are engineered to achieve specific hardness levels necessary for withstanding heavy loads and maintaining dimensional stability. T...

Contact Us

Your email address will not be published. Required fiels are marked